Discover Undercarriage Parts for Heavy Equipment

Comprehending the complexities of undercarriage components is crucial for the ideal efficiency and long life of hefty equipment. From track shoes to gears, rollers, and idlers, each part plays a crucial role in the functionality of the devices. Looking into the specifics of these components introduces a globe of accuracy design and sturdiness that maintains heavy machinery operating at its peak. Stay tuned as we uncover the significance of undercarriage parts and check out the maintenance techniques that can boost the effectiveness of these vital parts.

Importance of Undercarriage Parts

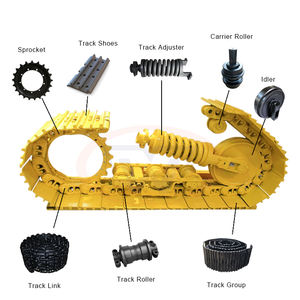

The undercarriage components of heavy equipment play an essential duty in ensuring the general performance and durability of the devices. These components, including tracks, rollers, chains, idlers, and sprockets, form the foundation whereupon the machine runs. A properly maintained undercarriage not just provides security and support to the hefty equipment but also adds considerably to its functional performance and productivity.

One of the essential benefits of buying premium undercarriage components is the reduction of downtime and upkeep prices. By utilizing long lasting components that can endure the roughness of sturdy applications, drivers can lessen the demand for regular repairs and replacements, hence taking full advantage of the maker's uptime and total life expectancy.

Additionally, effectively operating undercarriage parts make certain optimum weight grip, circulation, and maneuverability, enabling the heavy equipment to run smoothly also in tough surfaces. This dependability is vital for sectors such as building, farming, and mining, where tools efficiency straight affects project timelines and earnings. In verdict, the significance of undercarriage parts can not be overstated in preserving the effectiveness and durability of hefty equipment.

Kinds of Track Shoes

When thinking about the numerous sorts of track shoes for heavy machinery, it is important to review their design and capability in relation to details operational requirements. Track shoes are vital elements of the undercarriage system, giving security, traction, and weight distribution for heavy equipment such as excavators, bulldozers, and spider cranes.

The most common kinds of track shoes include:

** Grouser Shoes **: Including raised steel bars (grousers) along the footwear's surface area, these track shoes provide enhanced grip in challenging surfaces like mud, snow, and loose gravel. undercarriage parts.

** Dual Grouser Shoes **: Similar to grouser footwear yet with an additional collection of grousers, these track shoes supply also better grip and security, making them perfect for extremely harsh surfaces.

** Three-way Grouser Shoes **: With three sets of grousers, these track shoes supply maximum grip and security, making them appropriate for the most requiring problems.

Choosing the appropriate sort of track shoe is crucial for enhancing the performance and durability of hefty machinery while guaranteeing safety and security and performance during procedures.

Function of Rollers and Idlers

Rollers and idlers play important duties in sustaining and leading the track shoes of heavy equipment throughout pop over here procedure. By preventing too much slack or tightness in the tracks, idlers contribute to the overall security and performance of the equipment.

Additionally, rollers and idlers collaborate to maintain the track footwear in alignment, avoiding them from sliding or derailing off during procedure. Properly operating idlers and rollers are vital for ensuring the durability of check this site out the undercarriage system and maximizing the machine's effectiveness. Routine maintenance and evaluation of these elements are crucial to recognize any kind of signs of wear or damages early on, avoiding pricey repair services and downtime over time.

Role of Gears in Equipment

Maintenance Tips for Undercarriage Parts

Efficient maintenance of undercarriage elements is important for making certain the long life and optimal efficiency of heavy machinery. Routine assessment of undercarriage parts such as track chains, rollers, idlers, gears, and track shoes is crucial to protect against unforeseen breakdowns and pricey repair services. It is additionally crucial to guarantee correct track tension to prevent early wear on elements.

Final Thought

To conclude, the undercarriage components of hefty equipment play a critical role in ensuring the smooth performance and longevity of the devices. Recognizing the significance of track shoes, sprockets, rollers, and idlers, in addition to executing proper maintenance methods, can considerably affect the overall performance and effectiveness of the equipment (undercarriage parts). Normal examination and timely replacement of worn-out parts are vital in optimizing the lifespan and performance of heavy equipment

Rollers and idlers play essential functions in supporting and guiding the track go to this website shoes of hefty equipment during procedure.In hefty machinery, gears offer a vital function in moving power from the engine to the tracks, enabling the equipment to move effectively and successfully. These parts are attached to the axles or last drives of the equipment and job in conjunction with the tracks to propel the devices onward or in reverse. Normal assessment of undercarriage parts such as track chains, rollers, idlers, sprockets, and track footwear is crucial to prevent unanticipated malfunctions and costly repair services. Recognizing the value of track footwear, sprockets, idlers, and rollers, as well as applying proper upkeep methods, can substantially affect the general performance and efficiency of the machinery.